What causes pesticide applications to flop? It could be spraying at the wrong rate, or the wrong stage. Environmental conditions like temperature or humidity could be the culprit, or the mysterious mineral soup that is your water source. But there’s one simple, and entirely preventable reason a pesticide may be underperforming – the right adjuvant is missing.

Within the adjuvant classification, there are two main types – utility modifiers (think logistics - things like water conditioners, defoamers, etc.) and activator adjuvants (the Robin to your tank’s Batman, boosting your pesticide efficacy). Activator adjuvants are regulated by the Pest Management Regulatory Agency (PMRA) and if the label says to add one, they’re essential, not just a nice-to-have. This is because the product is registered to perform only with the addition of the adjuvant - without it, the product won’t work as intended.

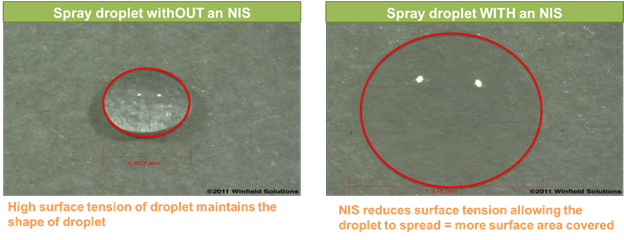

There are many types of activator adjuvants including oils and surfactants. Today’s focus is the humble-but-mighty non-ionic surfactant (NIS). They’re not flashy, but they play a crucial role in spraying success. Quite simply, surfactants help the pesticide stick and spread across the leaf surface, reducing droplet bounce through reduced surface tension. This reduced surface tension also helps droplets enter the plant stomata like Antman crawling through an engine.

Image source:WinField® United Solutions, 2011.

NIS are also emulsifiers which help to break the surface tension of the water. This dynamite combination allows them to bind well with pesticides and mix well with water. Surfactants can increase droplet coverage by 4.5x1 compared to droplets without surfactant. Additionally, they increase humectancy (keep the leaf wetter, longer), a benefit that is essential when humidity is dropping faster than morale during sprayer breakdowns. Not just critical for performance of many herbicides, surfactants are also required with many fungicides.

Not All NIS Wear Capes (or should be in your tank)

Despite all falling into the same category, what’s inside the jug can vary considerably and NIS are not all created equally. Different formulations mean different concentrations of active ingredient. It’s also important to avoid the undesirable ingredient Nonylphenol Ethoxylate (NPE), which is banned in some parts of the world. NPE has been linked to Arrested Ear Syndrome when applied to corn during the V5 to R1 stages, a time when your crop should be thriving, not stalling.

A few of the more common NIS found on the prairies include:

- Agral® 90 = 90% NPE or 92% NPE depending on formulation

- AgSurf® II = 92% Alcohol ethoxylate

- HiActivate® = 900g/L alkarylpolyoxyethylene glycols, free fatty acids, and isopropyl alcohol (IPA)

- LI 700® = 80% surfactant blend

- MasterLock® = 100% surfactant blend

- Pro-Surf II™ = 900g/L Alkylarylpolyoxyethylene glycols, free fatty acids and IPA

The Essential Duo: Fungicide + NIS = Full Strength

Without the addition of an NIS when it is a label requirement, performance will be reduced. Ensure the tank mix includes one.

Now that we know the composition of common NIS, and the role of NIS in the plant, what fungicides require, or have an optional add on, of an NIS? These include:

Guardian of the Sprayer: MasterLock Delivers

MasterLock is a WinField® United NIS powered by DropTight® technology for the added benefit of drift control and deposition. This means that in addition to getting an industry leading NIS, the spray will also be able to better penetrate a deep canopy. Getting fungicide to the base of the plant is often critical for optimal performance, and MasterLock delivers.

This unbeatable combination plays a key role in keeping plants healthier, longer and our Independent Ag Retail partners agree.

“I recommend MasterLock because it's easy to use and works really well with fungicides that require a non-ionic surfactant, all while still providing the spray drift control we’re looking for,” says Kaitlyn Davey, Sales Agronomist with Shur-Gro Farm Services in Westbourne, Manitoba.

The experience of Davey is echoed by fellow Manitoban, Ryan Tolton and Sales Agronomist and Operations Lead at Redfern Farm Services in Hamiota.

“I like recommending MasterLock with fungicides to help them penetrate a thick crop canopy and get to the base of the plant. Visually I’ve seen improved disease control and herbicide response where MasterLock has been used, and I can see the benefit compared to the application with a standard NIS only product.”

Experiences like Tolton’s are seen in spray paper demonstrations that WinField United regularly performs throughout the winter months at Spray Clinics.

This increased coverage isn’t just theory but also translates to yield. In 14 WinField United US studies across eight states from 2012-17, corn treated with MasterLock delivered an average 5.7bu/ac yield advantage. Similar results were seen with canola2 and wheat3, reinforcing MasterLock’s value across a range of crops. With proven benefits in deposition, and industry leading drift control, MasterLock has earned its place as a go-to tank mix partner, bringing performance and precision when included.

Go Mix that Tank!

When it comes to maximizing pesticide performance, skipping the right adjuvant—especially a proven NIS like MasterLock—can cost you yield and return. With enhanced coverage, better droplet retention, and consistent results across multiple crops, it’s not just an additive—it’s a competitive edge. In a world where every bushel counts, make sure your tank mix is the caped crusader your crops deserve and working as hard as you are.

1. WinField United Solutions data 2011

2. WinField United Canada Farmer Field Trials in 2023 at 13 sites across three provinces found an average gain of 2.3bu/ac with MasterLock + fungicide compared to fungicide only.

3. WinField United and WinField United Canada studies from 2019-2021 on 12 test sites found an average gain of 3.7bu/ac with MasterLock + fungicide vs. fungicide only.