As summer days slowly begin to shorten and crops change from luscious green to finish line gold, it’s time to gear up for harvest. Like any great race, a clean finish starts with a strong strategy—and making the right pre-harvest decisions sets the pace.

To Desiccate or not to Desiccate?

Growers have reliable options for getting the crop across the finish line—natural dry down, swathing, or spraying. If the field is clean, and conditions have been hot and dry, natural dry down may be sufficient. Swathing can be the best choice for crops that have uneven maturities, are more prone to shatter losses due to a lack of pod integrity or have thin and unhealthy plant stands. If spraying is your preferred path, it’s time to pick your ride: are you going with the steady endurance of glyphosate or the high-speed punch of diquat?

Think of glyphosate as a minivan. Glyphosate plays the long game—it gets the job done eventually, but is built for endurance, not speed. Diquat? That’s like a stockcar. Fast, aggressive, and unapologetic, it puts your crop on the harvest track without the drag.

Why Diquat over Glyphosate?

In crops where both products are registered[1], glyphosate is a great fit when perennial weeds are the predominant concern rather than a need to race to the harvest finish line. Diquat, on the other hand, excels when the goal is a quick, uniform dry-down to keep harvest on a winning path. Diquat is a Group 22 herbicide and works by breaking down cell walls – essentially giving the plant a flat tire – making the plant ‘leaky’, and water escapes. Unlike glyphosate, however, diquat does not kill the plant, it merely dries it out. If rainfall happens, or the crop is left in the field too long after the diquat application, re-growth will occur. However, a key benefit of diquat is that it does not affect germination of the seed, making it a safe choice for pulse applications where saved seed is part of next year’s production plan.

Diquat: The Pit Crew’s Choice

True desiccation means fast and even dry-down without compromising seed quality or delaying harvest. Diquat delivers on that, but as with any effective tool, application technique makes all the difference.

Success hinges on five key factors:

-

Water volume

-

Surfactant

-

Water quality

-

Coverage of whole plant – droplet size matters!

-

Application timing

Water Volume

All diquats are contact products and therefore water volume is important. Labels usually call for 24 gallons per acre as a minimum water requirement, and the race will be won by ensuring thorough coverage – water volume matters. More water will help get coverage deeper down into the canopy for more consistent results, particularly in dense canopies.

Surfactant

Water alone won’t win the race if your spray isn’t sticking and spreading on the leaf. The addition of a non-ionic surfactant (NIS) like MasterLock® or HiActivate® is required for most diquat products registered for Western Canada – it’s like traction control for your tank mix. Additionally, once droplets dry on the leaf they can no longer be absorbed by the plant. The humectant properties of MasterLock help the droplets stay wetter longer, improving absorption.

Water Quality

You wouldn’t put dirty diesel in your high-performing engine, so don’t put turbid water in your tank. Diquat is affected by the presence of particles in the water that create turbidity[2]. If using a dug-out, ensure the water is clear and clean. Manage your water source to eliminate algae and should the water be visibly contaminated, find an alternate source to use with diquat.

Coverage at the Base of the Plant

To get to the finish line, you need full plant coverage from top to bottom. While not a weed control product, diquat will dry down existing weeds that may be hiding under the crop canopy, clearing the track for an easier harvest. Even in a clean field, getting diquat to the base of the plant is vital for a thorough dry down. Penetration to the plant base can be more successful with the addition of a LockTech® product from WinField® United, such as MasterLock. LockTech products offer drift control to keep the spray on target but also alter droplet size to eliminate fine droplets and get the spray penetrating to the base of a thick canopy. This is a worthy tank-inclusion with diquat.

Droplet size is an important factor for coverage. Use droplets that are medium to slightly coarse to keep the spray on target and get it into the plant.

Application Timing

There is more to application timing than just the stage of the crop. When it comes to diquat, time of day is also a huge factor for success. Diquat works through the photosynthetic pathway and is therefore best applied in low-light conditions such as in the evening or overnight, so that the product can be absorbed properly prior to sunshine kicking it into gear.

What Diquat to Choose?

Just like many models of potentially race winning cars exist, so do brands of diquat, with both all-in-one (surfactant included) and 240g/L (no surfactant built in) brands available.

Armory All In™ is a 200g/L diquat concentration that is registered for pulses and oilseeds. It requires a minimum of 20gal/ac of water and includes the NIS directly in the jug.

The two 240g/L brands that we will look at are DriFast™ from Nufarm and Armory® 240 from ADAMA®.

Both products:

-

Are a 240g/L diquat concentration – because this is a higher concentration than all-in-one formulas, a lower application rate exists.

-

Can be used as a desiccant on pulses and oilseeds.

-

Require the addition of an NIS at 0.1% v/v.

-

Require a minimum water volume of 24 gallons per acre.

There are some differences between crop type and application (ground vs. aerial) method regarding application rates and the label should be consulted for further direction. Additionally, Armory 240 is registered for potatoes. Both options conveniently come in bulk drums or totes as well as jugs.

Reminder: Glyphosate isn’t a desiccant, but it can still help you cross the finish line

A pivotal point to remember is that glyphosate is not a desiccant – it is a perennial and annual weed control product. This helps to prepare your crop for harvest by killing the green weed material that may otherwise slow down the combine and contaminate your sample.

But, if glyphosate is your product of choice to help prep your field for a smooth final lap, knowing your timing and water quality will keep your operation rolling at top speed.

Know Your Timing

Timing is everything, so don’t jump the gun with a false start. For a clean, legal finish, glyphosate use is limited to when pulse or cereal seed moisture is less than 30%. This means the least mature areas of the field have to be lower than 30% for a green light, not the most mature areas. Glyphosate use is also restricted by crop and end use – for instance, glyphosate can’t be used on malt barley, but feed barley is acceptable. Market restrictions around glyphosate use are ever changing so consult www.keepitclean.ca before you hit the throttle.

Water Quality

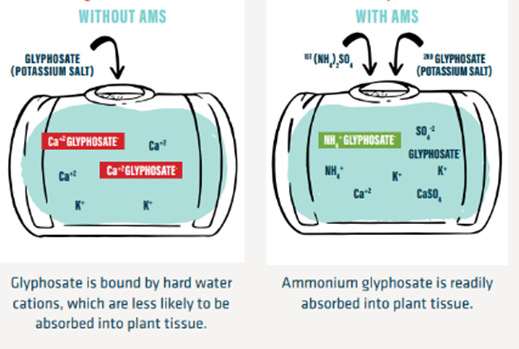

Just like a high-performing engine needs clean fuel, glyphosate needs good water for peak performance. It’s highly sensitive to poor water quality, so it's worth a quick water test to know what kind of mix you're working with. As shown in the image below[3], when cations such as calcium or magnesium are present they bind to the anions on each glyphosate molecule, making it less available to the plant. When an ammonium sulphate water conditioner is added, such as Crimson® NG, the cations bind with the sulfate instead, leaving the glyphosate fully available.

Crimson NG is an ammonium sulfate product offering a proprietary blend of water conditioning, coupling, and antifoam agents. It can be added from 1 to 2.5% v/v at the start of the tank-mix to prevent herbicide antagonism due to hard water and keep your tank firing on all cylinders.

Application Timing

Timings will vary depending on the crop and product being used. Diquat can only be applied on a plant with a sealed pod, so no cereals. Glyphosate use, as outlined above, is restricted by the type of crop. One important thing to keep in mind is staging for diquat on canola. When swathing, general recommendations are for 60 - 80% seed colour change (SCC). This means at least one seed in a middle-to-top pod has at least a spec of brown on it. This shouldn't be mistaken with color change for diquat. Diquat is to be applied when 90% of the seeds are fully brown, which is well beyond 90% SCC. This is a significant difference that will quickly put your harvest in a tailspin if not applied properly; an early diquat application will lock in a high green seed count.

Crossing the Finish Line

If you have time to wait and weeds to manage, glyphosate may be the right tool. If you want a dry-down that puts you ahead of the pack, diquat is how you race and Armory All In, Armory 240 or DriFast can help you out. Regardless of what choice you make, ensure you have the right tools dialed in for success and aren’t coasting on cruise control from earlier herbicide applications. For more information about desiccation, reach out to your local WinField United Independent Ag Retail.

[1] Always read and follow label directions and be mindful of MRL requirements for marketing

[2] https://canadianagronomist.ca/water-quality-can-affect-herbicide-performance/

[3] Image courtesy of WinField United, 2025